🚀 Fast-Track Launch

🛡️ Regulatory Shield

🔬 Innovation Lab

Your Premier Private Label Face Care Manufacturer

Combining Advanced Bio-Fermentation Technology with MoCRA-Compliant Manufacturing. Scalable Solutions for Visionary Brands.

Face Care Products We Manufacture

We manufacture a complete range of facial care products commonly used in daily skincare routines.

Face Cleanser

Clean Without Stripping

- Gel cleanser

- Foaming cleanser

- Cream / milk cleanser

- Amino acid–based cleanser

Face Moisturizer

Balance & Hydrate Daily

- Hydrating toners

- Light exfoliating toners

- Alcohol-free and fragrance-free options

Face Anti-Aging

Support Skin Over

- Hyaluronic acid serum

- Niacinamide serum

- Vitamin C derivative serum

- Peptide-based serums

Face Whitening

Brighten & Even Tone

- Lightweight gel creams

- Daily moisturizing creams

- Rich creams for dry or mature skin

Face Repair

Restore Skin Comfort

- Clay masks

- Wash-off masks

- Sleeping masks

- Sheet masks

Chat with us now for your Custom needs. Chat on WhatsApp Now

Face Care by Skin Concern

How Brands Usually Plan Lines

Brands rarely think only in “products”; they think in skin concerns.

Below are the most common face care directions we support:

Typical combination:

Gentle cleanser

Hydrating toner

Hyaluronic acid serum

Daily moisturizer

Used by brands targeting daily skincare users and sensitive skin.

Often includes:

Mild cleansing product

Niacinamide or vitamin C–based serum

Lightweight cream

Important note: claims must be aligned with regulations and ingredient levels.

Common structure:

Cleanser

Treatment serum (peptides / retinol where allowed)

Rich cream

Anti-aging lines require extra attention to stability and consumer expectations.

Typical elements:

Balancing cleanser

Lightweight serum

Non-greasy gel cream

Often requires careful ingredient selection to avoid irritation.

Functional Focus &

Common Active Ingredients

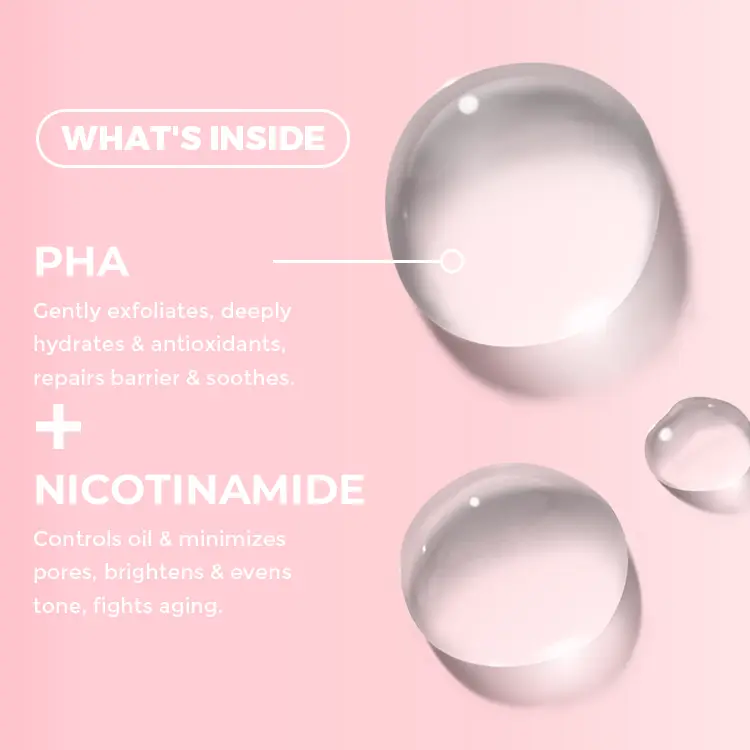

Active Ingredients Commonly Used in Face Care

We work with widely accepted and commercially proven ingredients, including:

Hyaluronic Acid – hydration and skin comfort

Niacinamide – tone balance, oil regulation

Vitamin C Derivatives – brightening support

Peptides – anti-aging positioning

Ceramide-type ingredients – barrier support

Botanical extracts – soothing or marketing differentiation

We generally recommend starting from stable base formulas and adjusting rather than developing overly complex formulas at the beginning.

Formula Maturity & Customization Approach

Mature Base Formulas

Many face care projects start from existing, production-tested formulas

These formulas have already been manufactured at scale and adjusted for stability

Customization Scope

Brands typically customize:

Texture (lighter / richer)

Fragrance or fragrance-free

Ingredient emphasis (within safe limits)

Packaging compatibility

This approach helps reduce development risk and time to market.

Chat with us now for your Custom needs. Chat on WhatsApp Now

OEM / ODM Manufacturing Process

How Face Care Products Are Developed and Produced

1. Project briefing & product direction

Confirm product type (cleanser, serum, cream, mask), target market and basic positioning.

2. Formula selection & adjustment

Select a suitable existing formulation framework and make necessary adjustments

(ingredient ratio, texture, fragrance or fragrance-free).

3. Sample development

roduce samples for evaluation.

Typical sample lead time: 10–20 days, depending on formula complexity.

4. Sample confirmation

Finalize texture, performance and basic specifications before production.

5. ackaging selection & compatibility check

Confirm bottle, jar or tube type and check compatibility with the formula.

6. Quotation & order confirmation

Confirm MOQ, unit cost, lead time and production schedule.

7. Mass production

Bulk production based on confirmed samples and packaging.

Typical production lead time: 4–8 weeks after final confirmation.

8. Quality inspection & batch documentation

Each batch follows internal quality checks with production records.

9. Packing & shipment preparation

Products are packed according to order requirements and prepared for shipment.

This process is designed to keep formula stability, production consistency and delivery timing predictable.

Packaging & Texture Matching

Common Packaging Options for Face Care Products

Facial Cleansers

Gel / cream / foam textures

Pump bottles, foaming bottles, soft tubes

Facial Serums

Liquid or light serum textures

Dropper bottles, airless pump bottles

Face Creams & Moisturizers

Lotion / gel-cream / rich cream

Jars or airless pump bottles

Face Masks

Clay / wash-off masks → jars or tubes

Sheet masks → sachets + outer box

Sleeping masks → jars or airless bottles

Chat with us now for your Custom needs. Chat on WhatsApp Now

Quality Control & Product Testing

Standard Quality Practices Across All Product Categories

Raw material inspection

Formula verification before filling

In-process quality control

appearance texture viscosity filling weight are checked at defined stages.

Batch traceability

raw material batch numbers production date filling and packing records

Basic product testing

stability observation compatibility with packaging basic microbial checks

Finished product inspection

correct packaging labeling accuracy appearance consistency

Flexible Manufacturing Designed for Growth

"Agile Supply Chain. We understand that speed and flexibility are currency in the beauty industry.

Low MOQ Private Label

Start with as few as 500 units using our stock packaging and formulas. Launch in as little as 4 weeks.

Scalable OEM

For custom formulations, our automated lines can produce over 100,000 units per day, ensuring you never face an out-of-stock crisis.

Global Logistics

Our logistics team handles export documentation, MSDS, and freight forwarding, delivering directly to your warehouse or Amazon FBA center.

Chat with us now for your Custom needs. Chat on WhatsApp Now

Frequently ~

Asked Questions

Can you copy another brand’s face care product?

Yes.

Many projects start from a reference product or existing sample. We evaluate texture, ingredient direction and feasibility, then develop a similar formulation based on our production-tested frameworks.

Exact duplication is not guaranteed, but performance and texture can usually be matched within practical and regulatory limits.

Can I start with a small face care line?

Yes. Many brands start with 3–5 SKUs and expand after market testing.

Do you support clean or fragrance-free face care?

In many cases, yes — as long as stability and safety can be maintained.

How stable are your face care formulas in long-term production?

All formulas used for mass production are selected or adjusted with stability and repeatability in mind.

We avoid formulations that work only at lab scale but are difficult to reproduce consistently in bulk.

For most face care products, stability and packaging compatibility are checked before mass filling.

Can I adjust ingredients after sampling but before mass production?

Yes, minor adjustments can usually be made after initial sampling, such as:

fragrance level

viscosity

ingredient ratio (within safe limits)

Once the final sample is confirmed, the formula is locked for production to ensure batch consistency.

Let’s Talk About Your Cosmetic Manufacturing Project

Working with skincare and personal care brands in Europe and North America.

We focus on steady quality, practical communication and realistic timelines.

- A human reply, usually within 12~24 working hours

- A clear first assessment of whether your project looks feasible

- Transparent discussion of MOQ and basic cost structure

- Confidential handling of your brand and project information